Maybe for Tom Cruise but not for Meder Kamalov, master of mixtures. For our very own in-house doctor of chemistry who is responsible for research and development, is no mixing ratio too complicated and no quantity survey too difficult. And these are exactly the topics which he discusses in today´s blog entry.

Stage clear for – Kamalov. Meder Kamalov.

*****

Let´s say you were tasked with the mission to prepare one hundred litres of vodka, but you cannot do it via fermentation or distillation as usual. Instead, your boss only gives you the basic ingredients of vodka – water and ethanol (commonly called “alcohol”).

The alcohol percentage of vodka is 40 percent (of course we only know that from propaganda). So you could first try to mix 40 litres of vodka with 60 litres of water. But if you consequently measure the volume of the mixture you will realise that instead of 100 litres, you only have approximately 97 litres.

What happened?

Imagine, you have the same task but now with tennis balls and sand instead of water and ethanol. Would the mixture of 40 litres of sand and 60 litres of tennis balls result in a total volume of 100 litres? Of course not. A share of the sand would simply trickle in between the tennis balls and increase the density of the mixture, but not without increasing the volume.

Small Excursion: The calculation becomes significantly simpler when you work with mass instead of volume. 40 kilograms of ethanol and 60 kilograms of water always add up to 100 kilograms. The law of conversion of mass is responsible for that: the sum of the mass of the starting material equals the sum of the mass of the products.

Simply put with the typical conundrum of What-is-heaver-a-kilo-of-feathers-or-a-kilo-of-iron: a kilo of feathers and a kilo of iron always add up to two kilograms. But a litre of feathers and a litre of iron sum up to far less than two litres because the heave iron squashes the feathers.

The situation with water and ethanol is slightly more complicated as they contain a lot of molecular kinetics and fluid dynamic, but the result is the same: we get a denser mixture. That means that the mixture density cannot be calculated from the components because it is depending on many other factors. For example, for the sand-ball mixture we would need to know the diameter of the balls and the flow ability of the sand.

Mixing – and then?

At injection sites you are often confronted with the same problem: materials are being mixed together dissolved in each other – as the two ingredients of the 2-components-polyurethane foam, cement suspensions or acrylate gels in which salt is dissolved as accelerator. At the construction site it is interesting for example how many grams of an accelerator (like salt) are dissolved in a mixture of 40 litres. Now, the knowledge of the components´ density is decisive.

In other words: if you have 125 ml of vodka-orange in front of you, how much water was used? To calculate this quantity, you need to know the components´ density.

Usually, however, the measuring device measures the total volume only afterwards. This is problematic as it is nearly impossible to determine the quantity of the components and to assure the quality of the mixture in retrospect.

Simple mass calculation with SCALES

The material management of SCALES makes this calculation possible. The program is able to track the exact consumption of the materials and to output mixing recipes for various batch sizes – regardless of the fact that different manufacturer information count on different units (sometimes it´s litres, sometimes it´s grams, …).

To calculate the exact density and recipe of the mixture, users have the possibility to enter the total volume of a comparable mixture. For example, if you mix together 20 litres of component A with 20 litres of component B and one litre of component C, you get 40 litres in the end.

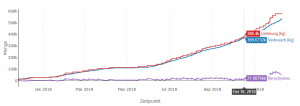

Based on this information, SCALES can calculate the mixture density and thus, the exact quantities of the components of each mixture in volume and mass and through this, it can output recipes for the various batch sizes. This allows our users to carefully monitor how much of each substance is used on different job sites and how they are installed. This way, you will always know the exact consumption values of all available ingredients in a specific period at a specific location.

Unlike common measuring devices, the program of SCALES measures before AND afterwards; Before, so all the equipment can be set correctly, and afterwards, to track the consumption of each material. So the user always knows how long the supplies last. As a result, the quality of the built-in injection grout can be ensured and the material level can always be tracked on the construction site.

He who works with SCALES does not need to lose a thought about complicated equations and always knows exactly the material levels.

*****

Author: Meder Kamalov

Meder has truly come from far away to us. On the one hand, he is originally from Kyrgyzstan (a round of applause for everybody who can find it on a map at the first go without internet …). On the other hand, he actually did a PhD in chemistry (in New Zealand, which is also not exactly around the corner) and as well teaches it at the University of Vienna. But with us it´s just more exciting – and nicer – so he decided to switch from chemistry to software development. Good choice!

Picture credit: Pixabay