Distance learning, Zoom-conferences, theatre visits via the own laptop. Due to the corona-related social distancing and the associated home office, digitisation has been boosted in Austria which finally brought us into the 21st century. The construction industry too is realising slowly but steady that digitisation can simplify many processes – and thus safe money.

Leopold Winkler from the institute for interdisciplinary construction process management at the TU Wien (research area construction operations and process engineering) can only agree with this. He wrote his dissertation on “Digital Data Management for Injections” and found out: digitising construction process management saves time – and thus a whole lot of money.

Collecting data with SCALES

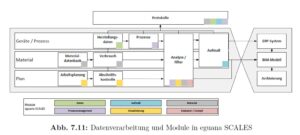

In a project supported by the Austrian “Forschungsförderungsgesellschaft FFG” (“Automatic quality management for the construction and environmental technology”), the eguanas worked together from 2016 to 2018 with the research area construction operations and process engineering to develop a wireless monitoring system. This should record the entire work- and production process of injection construction sites, adaptable to the individual users‘ demands. The measured values should not only be collected and presented, but also allow statements about the construction progress.

“We have scientifically accompanied the construction data monitoring project from eguana SCALES”, explains Winkler. “My dissertation resulted from this. On the one hand, I scientifically recorded the development of the work. On the other hand, I evaluated the added value for the construction site and the documentation process.” In the course of the research “it has emerged that digital data management on a construction site provides clarity about construction site processes and that they can also be optimized in daily construction operations”, Winkler continues.

More confidence in digital documentation is required

A survey he conducted with decision-makers revealed a divergence in the assessment of digitised data management. While developers expect a resource reduction by the usage, the saving time is priority number one for construction companies. Even though 87% of the respondents stand positive towards digitised data management, at the same time only 9% of the respondents have more confidence in this rather than manual documentation.

A closer look at the two pilot projects that were investigated in the course of the work shows that the hoped-for time savings in particular would benefit from more trust in the digitised construction data management. “Based on the two different projects, I determined which advantages can be derived compared to the old traditional process”, says Winkler: “The resulting time savings of the non-commercial staff in this study, which was supervised in a comparative period of 23 months, accumulates to about 122 hours per month.” In addition, the effort of the daily documentation processes could be reduced by 68%, that of the monthly measurement even by 83%. The prerequisite for this, however, is that the systems are accepted by everyone involved. This is the only way to achieve their full effect.

From the collected data sets of more than 120,000 injections which were recorded in the investigation period, Winkler could develop a real time construction time forecast model which can predict how long a construction procedure will take and how stable the construction process will be. The model can be implemented in digital data management systems and is suitable for other procedures in addition to injection processes.

Sounds great – but how to continue?

What is clearly demonstrated not only by the scientific work and the associated field studies: Digitisation is literally paying off. For all involved. But with so many things, it is important to think and plan ahead which changes will (or should) arise due to digital construction data management.

Here, Winkler sees two main points which should be considered at future projects.

Measuring and automatically evaluating KPIs

An important factor are KPIs (key performance indicators), which are generally used as a measuring unit to achieve the goals of a wide variety of projects. However, in order to know how far the achievement of a goal has already been achieved, the associated KPIs must not only be defined in advance, but above all must actually be measured and automatically evaluated.

In the course of the research work and the development of eguana SCALES, KPIs were integrated from the beginning. The progress of each single indicator can be tracked in the system. For Winkler, further research is resulting from this because “in the specific case of injection technology, the possibilities of alternative remuneration based on the KPI concept presented should therefore be fully examined.”

In the case of clearly defined elementary key figures, one should also consider adapting the ground laying contracts for projects so that these key figures are the basis for fair and transparent remuneration for all parties.

It would be conceivable that personnel and equipment deployment planning as well as key performance indicators are determined in partnership at the start of the execution and a bonus-malus system was then implemented in the implementation.

Documenting tunnelling process

According to Winkler, the second promising field of action for future development lies in the documentation of the conventional tunnelling. Herein, it would be possible to apply the “sequenced process suggestion”, described in the thesis, to the so called cycle diagrams and to integrate the already available process times into the model.

The work processes of the jacking team are currently documented manually, to then be manually transferred into digital systems – including all from this process resulting errors and redundancies. If the data is recorded digitally, this gives you the opportunity to determine the actual situation of the construction and compare it with the target construction.

For a meaningful implementation, in addition to extensive field tests, the interfaces of different device manufacturers must be released in order to be able to directly digitally record and process data.

In order to continue in the corresponding direction, more trust in the digitisation of systems and the willingness of the developers to invest in this will be required in the future. Winkler wishes that companies do not have to think through projects hierarchically in organizational structures, but in processes. “A successful construction execution is based on the intensive exchange of data and communication between all stakeholders. Digitisation gives us the opportunity to improve and automate these interfaces. However, this is only possible if companies are willing to work transparently.”

*****

About Leopold Winkler:

Dipl.-Ing. Dr.techn. Leopold Winkler studied civil engineering at the TU Wien as well as at the Politécnica de Madrid. He worked for various construction firms before graduating at the institute for interdisciplinary construction process management. In his research as a post-doc at the TU Wien he deals with digital data management at construction sites and the related process changes. For companies and start-ups, he supervises the evaluation of digitisation potentials and the implementation of digital construction tools. Expert work on construction and claim management complete his experience. Off the beaten track, he is a musician in the orchestra “Klangvereinigung” and enjoys various sport activities.