Water is known to be the source of all life. We came from the sea (and every summer we are drawn back there), we consist of 70% water, some of us take a shower every now and then (what I’ve heard). However, in the tunnelling industry people mostly refer to water as “the source of all trouble”. From above, from below; due to groundwater or rainfall – water ingress leads to problems which should already be accounted for in the planning and execution.

For our latest blog entry, we were able to get our long time project partner Sewerin Sabew from the department Marti Geotechnik of Renesco GmbH as guest author. He will give us some insights in the insulation of mountains containing anhydrite.

********

Challenges with the execution of chemical injections to insulate swelling rock

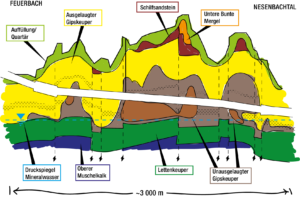

In course of the project Stuttgart 21 a new tunnel is being built, leading from Stuttgart central station to the train station in Feuerbach. Some sections of the twin-tubed tunnel go through rock mass containing anhydrite*. Anhydrite, also known under its chemical name calcium sulphate, is a common, crystalline mineral that turns into gypsum when in contact with water. As a result, it increases in volume and expands.

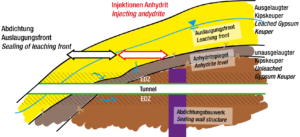

Therefore, the tunnel is always advanced dry (that means, that water ingress is being avoid during the advancement), but because of explosions or tension redistributions it can always happen that water ingresses from groundwater bearing layers. This can result in a substantial expansion of the rock volume. Due to swelling pressures occurring at past constructions of tunnels, they suffered considerable damage in the form of uplifting as well as ongoing complications and increasing costs due to the constant need for remediation.

For this reason, insulation measures are essential.

Insulation in three steps

For this purpose, the engineering office Wittke Beratende Ingenieure für Grundbau und Felsbau (founded in 1980 by Prof Dr Walter Wittke, Germany´s leading scientist of rock mechanics) a new injection concept. This envisages limiting the ingress of water by chemical injections (instead of relying on a sufficiently thick tunnel shell that removes swelling pressures).

The three steps of the injection concept:

- Preliminary injections in the course of the tunnel advancement when driving through water-bearing layers (this means that the surrounding area is already insulated before advancing to the next tunnel section)

- Systematic injections to insulate the anhydrite (now, the tunnel sections lying in the anhydrite are completely insulated to avoid water ingress into the anhydrite from the excavation-damaged-zone, caused by the drilling along the tunnel tube)

- Insulation constructions (so called dam-rings) to reduce the water permeability in the longitudinal direction of the tunnel, and to avoid that water runs in the longitudinal direction or along the tunnel (occurring problems are limited to one zone and do not affect the entire construction)

During the advancement of the tunnel and the formation of the inner shell, about 60,000 drillings have to be compressed along a distance of 3,000 metres. That’s up to 600 injections per day which not only have to be executed but also checked and documented.

Development of existing technologies

These measures require injectables that insulate water fast and reliable, but also show low viscosity so they reach even the smallest gaps. This again poses various challenges to the injection technique. To meet the high requirements, existing technology had to be further developed and new approaches had to be taken.

Polyurethane resin is used to insulate the water ingress as it shows higher viscosity than water. A special algorithm was developed to guarantee that the injection pressure in the drilling hole would lead to a tearing of the mountain. This algorithm considers the conveying resistance in the system and automatically regulates the injection pressure.

For the insulation of the mountain consisting of dry anhydrite, an acrylate gel is used which can be easier compressed due to its lower viscosity. For these injections, special, reusable pneumatic packers with ventilation were developed.

Further innovations include the development of an injection container*** for acrylate gel injections, as well as the use of highly accurate sensors for the exact measurement of the mixing rations of all components even with low conveying rates (originating in the process and pharma industry).

Manage data easily

Plans are always a nice thing to have and essential for constructions. However, what are even the best plans good for when the conditions change? And life is per se the manifestation of change – not least of all by changing our environment through constructions.

However, it is not only annoying, but above all costly, if changes occur during operation and planning and execution must be adjusted. Digitisation makes it easier to deal with change and is essential for agile project management.

Because you never know exactly what the geology will bring, it is essential to be able to react to changes in the injection planning instantly. The aim of the project coordinators has always been to use state-of-the-art technologies in the field of data and documentation management, to deal with these challenges efficiently and effectively. To efficiently execute the 120,000 injections (600 per day) in an extended back-step method** while keeping documentation at a minimum, the digital injection management system SCALES was introduced.

It allows access to injection data in real time, automated mass determination, material control, interactive visualisation, as well as exact documentation of construction processes. Evaluation of construction time, KPIs, effort and performance values are obviously integrated as well.

As an interface to superordinate systems like ERP or iTwo, it simplifies the communication between all involved. With this data and documentation system and the automation of logging, control and billing, the focus lies on the control and verification of the injections. This saves valuable time. Also, more attention can be given to essential matters to minimise errors of routine activities in the work process and to assure the desired quality.

To illustrate in which dimension digitisation simplifies the work: 600 injections per day – you would use up more than the usual copy paper package per day (!) to document all injection protocols – and then, someone would need to manually go through them and check every single one. An enormous effort (besides the waste of paper) which is reduced decisively by injection data management.

Agile methods in the execution

Agile methods have been implemented in many project management tasks, allowing the entire team to find a solution to every problem that arises. The challenge was to keep the focus on the big picture – the creation of a comprehensive documentation system. Thus, the project was developed step by step and led to success.

The use of agile development methods contributes significantly to securing the required quality, saving resources, making the implementation of tasks lean and flexible, and implementing them much faster and minimizing various risks. This way, time and resources could be saved (in spite of constantly changing conditions during execution).

The detailed planning of work packages that are far in the future and whose requirements and functions can change even before the development of this work step was started was not carried out. Flagrant discrepancies between the ideas of the project managers and the actual output were systematically and continuously avoided in this way. Success has not been measured by mere compliance with milestones, specifications, and record books created at the beginning of the project, but by the viability and usefulness of the data and documentation system, as well as the added value created for the site.

Step by step to the goal

From a philosophical point of view, we neither know where we came from nor where the journey is going. There is nothing left for us to do but take one step at a time and see where it leads us.

Luckily, we have a more precise idea of what the basic conditions are and where we want to end up. But realistically, we have to admit: “even though, a plan is smart useful it is still just theory”. So we have no choice but to accept that plans can only reliably help us over a certain distance.

Thus, it makes no sense to define a final product and to follow this definition to the end, no matter what. It is much more sensible to have a goal in mind and set the steps to reach it one at a time to be able to adapt to changes.

The result probably differs from what you had in mind at the beginning – but it is certainly better suited to meet the currently adjusted requirements. Regarding the many aspects: quality, reliability, durability – but also satisfaction and happiness to all involved!

********

It is not the strongest species that survive nor the most intelligent, but the ones most responsive to change. (No, not Darwin, but Leon C. Megginson)

********

We thank Sewerin Sabew for his expertise and are looking forward to future collaboration!

Guest author: Sewerin Sabew

Sewerin started his education at the institute of technology in Karlsruhe were he did his graduate engineer. After seven years as project manager at the Alpine Bau GmbH, he started to work at Marti Geotechnik in 2014 where he now is technical department manager. He likes to spend his spare time with philosophical reflections and thoughts on human psychology (because if you focus on the human, the good result comes by itself. Or as General Patton said “Never tell people how to do things. Tell them what to do, and they will surprise you with their ingenuity”).

*Gypsum Keuper is a widespread rock layer that swells when water ingresses. It consists of clay stones and retentions of gypsum, anhydrite and halite.

**This technique works according to the motto: “two steps ahead, on step back”. At first, it is injected in larger sections, then you go back to the start and –for the case that the geology requires further injections- inject in the small gaps. Each injection section is passed up to eleven times, up to three injections per drill.

***A project which represented an unprecedented and exciting challenge not only for the tunnelling industry, but also for eguana.

For those of our readers who are wondering why the text refers to Anhydrite while it says AnhydriD in our beautiful cover picture (thanks again to the creative Julia): An anhydride is a chemical compound that is made up of an acid or base is formed by dehydration. The word comes from the Greek (ánhydros), and as it translates to mean „waterless“ or „anhydrous“, the term was perfect for our cover picture. Anhydrite, in turn, is a mineral that swells up to gypsum by contact with water.