Too much of a good thing? Can also happen with injections. If too much material is injected into a crack, the gap can tear even further. Together with the Graz University of Technology, we are trying to find out as part of the HYJACK research project when the point has been reached at which one should say: Okay, that’s it, period.

*****

Building a tunnel sounds pretty easy to the layman: Take a shovel and dig a hole in a mountain. Just like the Dalton brothers periodically did in the Lucky Luke comics to dig out of prison. Of course, things are not that simple, and if the Daltons had actually acted like this on their escape, the tunnel over their heads would probably have collapsed and Morris and Goscinny would have had to come up with new opponents for their cowboy.

For the mountain to remain stable during the tunnel construction, to keep it from collapsing and water from entering (also not a nice end for the four unequal-sized brothers), injections are used to fill the small torn areas.

Still too simple to be true?

It is. Because if too much material or too much pressure is used, the cracks are not only filled but on the contrary they are enlarged even further. This means that more resources are required, injection times are longer than they need to be and the construction work is being delayed.

But when is the point where you should stop injecting? Together with the Technical University (TU) Graz we have been investigating precisely this question in a research project since June 2020. Our civil engineer and developer Cesare Schwabl paid a visit to Graz University of Technology in August to get an overview of the current state of affairs.

Point of no return

“We want to find out whether you can read from the measurement data when the point has been reached at which it is best to end the injection process,” he explains. We have been dealing with the topic for a number of years, and approaches to this were already presented at the Nordic Grouting Symposium 2019. On the part of the TU, the HYJACK project is accompanied by project manager Scott Kieffer from the Institute for Applied Geosciences and test manager Manfred Blümel from the Institute for Rock Mechanics and Tunneling.

“It is important for us to know the details of the data that we process and, above all, to understand it,” emphasizes eguana managing director Philipp Maroschek. “That is why we examine construction processes with our customers, partners and research institutions. As a result, we know the challenges our customers have to face and can help them and master their challenges together with them.”

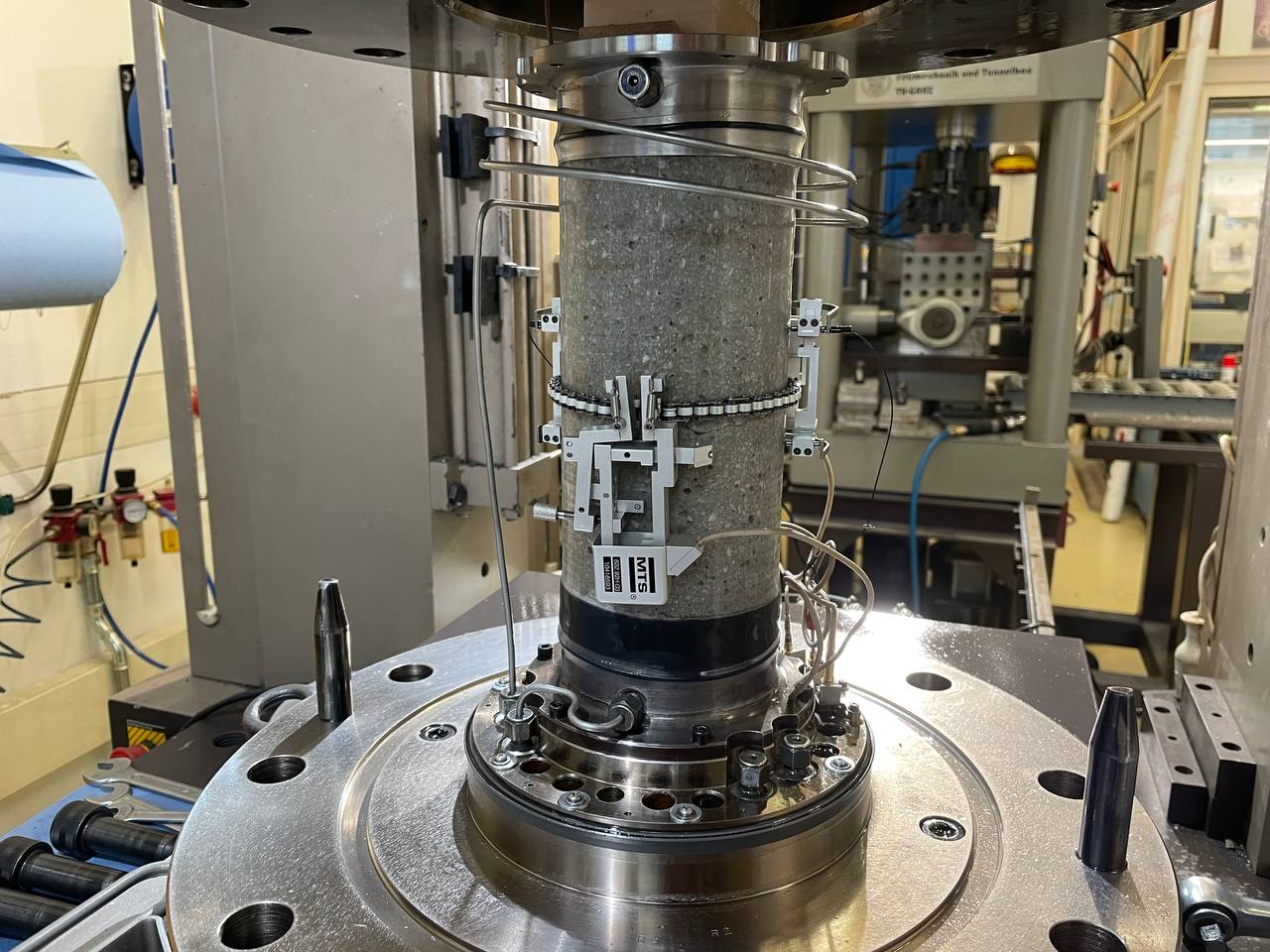

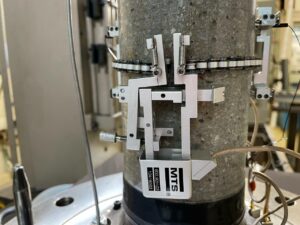

Put simply, the HYJACK test setup consists of a stone cylinder that was cut into two. The upper half is pressed against the lower half with pressure. A cavity runs through the middle of the lower half. During the course of the experiment it is filled with water. If enough pressure is created in this way, the upper cylinder lifts slightly from the lower one despite the counterpressure. This point in time as well as the applied flow rate and pressure are precisely documented and analyzed with a series of sensors and thus provides information about when the injection should be interrupted.

Sustainably better

The test series will run until the end of 2021 – until then, further tests will be carried out and we will collect and analyze data. The aim of our joint research work is to develop an algorithm can detect the rupture of fissures during injection processes at an early stage and intervene to control them, instead of just correcting them afterwards, as is currently being done. In the future, civil engineering should be of higher quality and resources should be used more sustainably.