Surveying technology under the magnifying glass

Just as Batman keeps a watchful eye on Gotham City and Yoda notices the smallest tremors in the Force, Boris Bogensberger keeps a close eye on every change. Just like the masked avenger the surveyor can currently be found a lot in underground (bat) caves, specifically those of the Vienna U2. We talked to the managing director of Bogensberger Vermessung ZT GmBH about how measurements are taken these days.

*****

Technology can move mountains – or make them higher. It has been more than sixteen years since Bogensberger, who was a student at the Vienna University of Technology at the time, together with two fellow students, scaled and measured the almost 7,000 meter high Aconcagua, the highest mountain in America. Not an easy task in difficult weather conditions with winds of up to 240 km/h – around 60 percent of the ascents fail. Well equipped, the group made it to the summit and using GPS found out that Aconcagua was four meters higher than previously assumed, namely a proud 6962.97 meters.

Technological progress

At that time, Bogensberger was still at the very beginning of his career, but it was already clear to him: Technological innovations mean enormous enrichment and also make work easier.

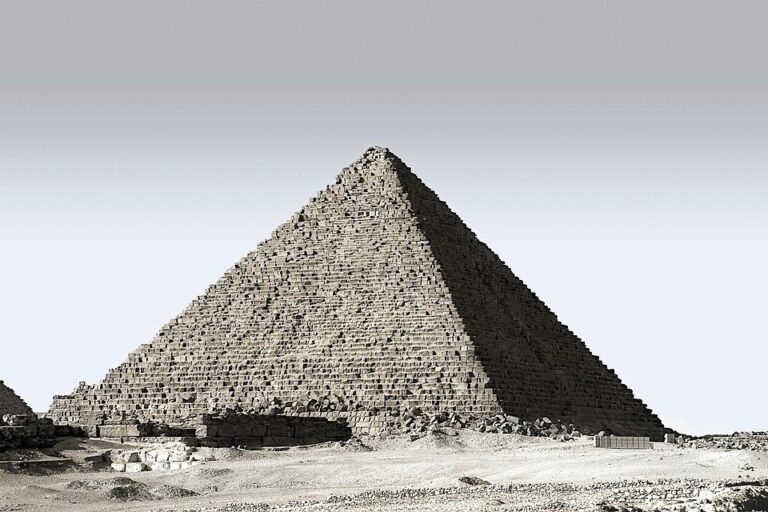

Measurements were already taking place in ancient times – only think back to mathematics lessons in the lower grades, where the distance between two points was calculated using the “Pythagorean theorem”. And without precise measurement and calculation, buildings such as the Colosseum, the Pantheon, pyramids or aqueducts would not only be unthinkable, but could not have been built in this shape and size.

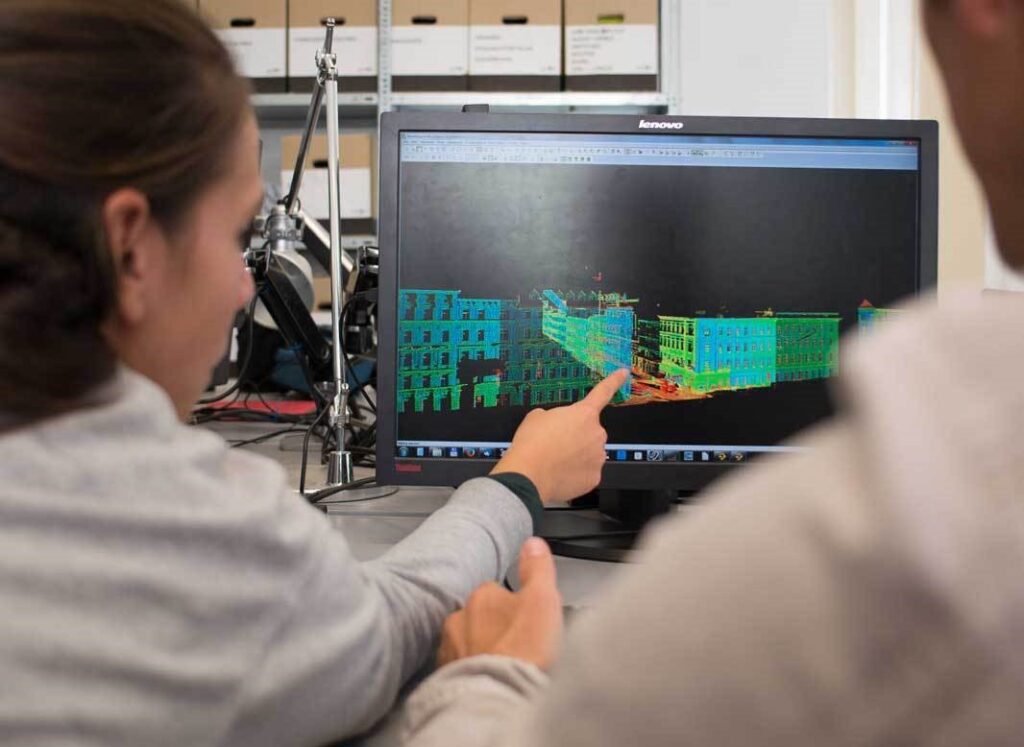

“When my father founded our company in 1982, ink and pen were still being used”, says Bogensberger, who took over the management of the company in 2007. A lot has happened since then, as digitization in combination with the Internet has brought about a paradigm shift in surveying. “The comprehensive internet means that measuring systems make data available in quasi real-time.” This is particularly relevant for building monitoring, where prompt decisions must be made if deformations occur.

Two kinds of measurement

There are basically two types of structure monitoring. The classic approach deals, among other things, with the detection of vibrations, moisture and cracks that affect existing buildings.

The geodetic approach, on the other hand, records deformations during the construction process, which provide different information depending on the measuring system. Geodesy uses a wide variety of sensor types in order to be able to draw conclusions about any load conditions. These monitoring measurements fall under the term Structural Health Monitoring.

While convergences used to be measured in the tunnel using relatively simple invar wires, this is now done by a measuring robot. These robots “approach mirrors mounted on the object at set intervals, measure angles and distances and can thus determine 3D deformations. All systems can immediately send an SMS or e-mail alarm when limit values are exceeded.” These technologies are used, for example, for landslides, securing excavations or track monitoring, but also increasingly in inner-city areas. Here, buildings and infrastructure objects that are in the immediate vicinity of construction sites are monitored.”

If, on the other hand, it’s about settlement instead of convergence, “water level gauges are the most accurate method on the market.” Water level gauges are used, for example, in the expansion of the U2 line in Vienna. For the main lot U2 17-21 (the route between Triester Straße/Matzleinsdorfer Platz and Augustinplatz) Bogensberger Vermessung is responsible for the design, installation and support of the gauge systems – and eguana is responsible for the data management.

A total of around 1,500 gauge sensors was installed in basements and canals across Vienna in order to monitor the construction work for the construction of the new subway tunnel across the board. In addition, there are around ten kilometers of hose and cable lengths and hundreds of liters of measuring liquid.

When to measure

In principle, measurements are taken both before and during construction. Baseline measurements (i.e. reference measurements before the onset of an expected change) “of adjacent infrastructure are sensibly made before construction,” says Bogensberger. Applied to the construction of the U2, this means:

Surrounding buildings that could be affected by the underground construction work will be surveyed before the construction work begins in order to have a reference value for possible changes. “During construction – depending on how high the risk is assessed – manual measurements are taken at defined intervals, for example monthly or weekly. However, if higher-frequency movements are caused by construction work, only automatic geomonitoring makes sense. Here, object movements are automated and monitored at short intervals of less than a minute.”

A large construction like that of the U2 is of course not easy. “Challenges in tunnel construction are fault zones of unstable geology. Sections where there is existing infrastructure in the immediate vicinity or even directly above are also particularly critical. This is the case in Vienna with lot U2 17-21.”

For this purpose, “settlement troughs were calculated and a total of around 90 objects are automatically monitored for settlement. For this purpose, the cellars are equipped with level sensors that record relative height differences in the buildings of less than one millimeter around the clock. In addition, hundreds of bolts are attached to the houses, which are monitored weekly by the city surveyor MA41 with leveling devices for settlements.”

For the systems used, the monitoring of the Viennese canals is a particular challenge. Due to the construction work, some gauges have to be installed in existing ducts. There is an immediate risk that the sensors will be submerged on days with heavy rainfall. “The systems must be designed in such a way that they are watertight and protected against corrosion,” says Bogensberger.

Measuring Manner

But things don’t always go smoothly above ground either. For example, part of the Manner factory in Vienna Hernals collapsed during construction work in 2014 – allegedly because the foundations had been undermined by cocoa slag (an idea that might be too much of a good thing even for hardcore fans of the waffles). In order to prevent further accidents (and to guarantee the smooth production of the cocoa waffles, thank you very much!), the company Bogensberger was called in and an automatic monitoring system was installed.

*****

Back to Batman: Anyone who now thinks measuring is boring number juggling – certainly not! Because as mentioned: If you want to measure a mountain, you first have to climb it. If you want to measure a tunnel, you have to go inside. And if you want to put hose scales in the basement, you have an exciting tour through the Viennese sewage system ahead of you. In 40 years of surveying, the Bogensberger family has also collected some exciting pictures. If you don’t want to miss out on the most beautiful impressions from 1977, the best thing to do is watch this video: https://www.bogensberger.com/dienstleistungen/35-years-young

We are very happy to be part of this journey – because just like Batman has Alfred, who brings him up-to-date, Bogensberger has eguana and SCALES.

*****

A big thank you goes to Boris Bogensberger, Managing Director of Bogensberger Vermessung and secret guardian of the city (respectively its buildings), for his time and expertise!