No, there are no canaries in the center on the mountain (ZaB, www.tunnellinghub.com) – there is no Balrog either. However, attentive miners can encounter foxes and snakes, explains Robert Wenighofer, research assistant at the Chair for Subsurface Engineering at the Montan University Leoben. Together with university professor Robert Galler he took us on an mental tour of the ZaB, a realistic, true-to-scale research and training facility. Due to the corona, there was no possibility of an official opening, but research, teaching and learning are already taking place deep underground in the middle of the Eisenerz Alps – and practice-oriented training is being raised to a new level.

*****

Zentrum am Berg (ZaB) – a research, development and seminar center for the construction and operation of underground facilities

Underground systems are essential components in the transport and energy infrastructure sector. Tunnels help handling inner-city and supraregional traffic and ensure security of supply. At the same time, they represent a cornerstone on which future successful economic development will be built. The shift of traffic and supply to underground infrastructure (which is visible everywhere) makes tunneling a major economic driver. The relocation brings major challenges for the construction, transport and energy companies with it, but also for the emergency organizations with regard to production and maintenance as well as warranty of the safety for their users.

However, there is no underground facility for research, development, instruction and training purposes for the further development of private companies and the relevant universities. The devastating tunnel fires around the turn of the millennium in particular demonstrated the need for much more interdisciplinary cooperation in order to master them. This fueled the efforts at the Chair of Subsurface Engineering at the Montanuniversität Leoben to develop a test center that allows research and training in safety issues on a 1:1 scale. Studies on a mere laboratory scale are of limited informative value and a realistic research environment produces more realistic research results.

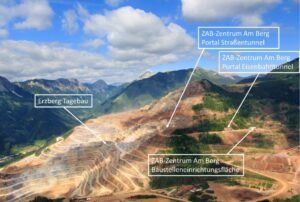

The Styrian Erzberg was mined underground until the 1980s, leaving many floors with old cavities and tunnels. One of these floors is ‘Dreikönig’, where the Zentrum am Berg (which translates into ‚centre on the mountain‘), the research, development and seminar center of the Montan University Leoben for the construction and operation of underground facilities, is located (Figure 1).

For the students oft he Montanuniversität, practice has always played an important role, even before the ZaB. Part of their studies was characterized by laboratory components; practical experience was collected in the professional environment of relevant companies. The possibility of a test center with realistic dimensions, however, takes practice to a completely new level, says Robert Wenighofer from the Chair of Subsurface Engineering, describing the project.

The Dreikönig floor is characterized by a very distinctive underground network of old tunnels and easy accessibility away from the mining operations of VA-Erzberg GmbH, which offered advantages over other underground mines located in Austria and led to this choice of location in the late 2000s. With the development of the idea (2006) the way led via a feasibility study, the planning and official procedures to the construction in the years 2016 to 2020. The teaching during the construction period succeeded by involving the students of the chair for subsurface engineering at the Montanuniversität Leoben in the construction operation.

However, the employment of student staff already took place in the planning phase before the tendering of the building project, so that a balance of tasks between the planner and the client of the project could be found that was conducive to the training of the students. The young colleagues experienced a currentless environment in complete darkness and tunnels not secured by retainings. As a result of thunderstorms falling outside, increased humidity and cold in the tunnels, they were periodically fogged and partly broken in the periphery. There are still sections of “currentless environment in complete darkness” in the ZaB; according to Wenighofer, these are suitable as “zero connectivity environment for underground training of security forces or armed forces.” The idea behind that is preparation for smoke as well as power and ventilation failures in case of underground attacks. The trainings “enable exercises under the influence of an area where sound and electromagnetic radiation (radio signals, communication, etc.) are subject to strong attenuation. In this environment one is confronted with different sensory perceptions than in the open field. “

Tunnel fire tests, excursions, seminars and courses (such as courses for blasts and shotcrete operator courses) were already held during the construction phase, and modern, non-contact measurement methods such as Unmanned Aerial Vehicle Fotogrammetrie were integrated into the construction process. After the end of the construction phase, it was now possible to continue the tunneling work by means of tests with construction equipment and training for miners. A major planned expansion of the underground facility is a subway station that is to be used for underground safety training.

Miners and security forces predominate in the training courses at the ZaB. The center is not used for cave exploration, as this takes place in unsupported cavities. “At the ZaB, the issue of safety is predominant in underground construction and in the operation of underground facilities”, says Wenighofer. “As a safe and extremely flexible construction method, the construction of NATM (New Austrian Tunneling Method) prevents collapses or fractures, as we call it. Thanks to advance exploration and route selection, no unexpected voids have occurred so far. “

A day underground

According to Wenighofer, there is no typical workflow: “Overall, the working days are quite different. Sometimes manholes are torn open in order to insert sample carriers for pipe materials from tunnel drainages and to measure pH values. Sometimes there are tours of a wide variety of university and non-university subjects. Sometimes fire tests take place with e-cars, explosions, smoke, fan tests, geotechnical monitoring measurements, etc. ” What does not exist, however, is the typical canary that warns of gas in the mountain – instead there was “ a construction site fox with its prints still visible in the concrete in the tunnel. Another time, during th construction phase, there was a snake.”

It takes a little less than an hour to get from the university to the ZaB – too long to stop by for a quick visit, but short enough for a “day trip”. Wenighofer has not yet found his personal favorite place, “the system is too new for that”, but “the fire tests with e-vehicles have been the most exciting so far.” Wenighofers most shaping insight during the preliminary exploration for the route planning and the construction phase was that “other professions such as geology and geophysics have much more confidence in the strength of bonds in a rock that has not been provided with retainings than I do.”

Sustainability aspects also play a role underground. Recycling of excavated material is becoming more and more important, and “energy research on underground storage media such as compressed air and water is also a mainstay of the scientific world of the ZaB.”

ZaB provides a remedy

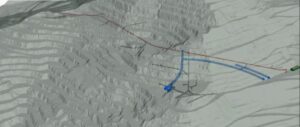

In short, the ZaB provides a remedy for daytime research, which is suffering from the urgent high availability of tunnels, by providing several hundred meters of representative environment in the form of underground infrastructure for various modes of transport road tunnels (2-lane) and railway tunnels as well as the existing tunnels of the Erzberg (Figure 2) and for in-situ tests. Construction measures to date include the construction of the pre-cut railway tunnel (Figure 1) in summer 2016, the establishment of operating buildings for training and ventilation purposes, and the main driving of railway and road tunnels (September 2017 to May 2020).

With the implementation of this forward-looking project, Austria gains a unique selling point of use for all of Central Europe. With this project, Austria is signaling a forward strategy that will achieve positive effects for the business and science sectors, opening up a wide range of possible uses that combine research and development from a wide variety of disciplines.

Wenighofer is certain that the future will be shaped by more underground infrastructure for mobility purposes, which is why he would like the ZaB to see more of the security forces exercising underground hazards (as can be seen in Figure 3) and thus “safety facilities in underground systems (fire extinguishing / breakdown niches in road tunnels, subway) for everyday road users could lose the nimbus of strangeness/untouchability. “

*****

Many thanks to our guest authors Univ. Prof. Dipl.-Ing. Dr.mont. Robert Galler and DI Robert Wenighofer from the Chair of Subsurface Engineering at the Montanuniversität Leoben for the exciting contribution!